VIDEO

Metal Injection Molding Process

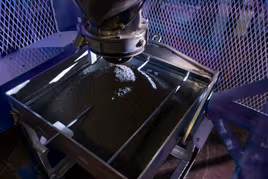

Metal Injection Molding (MIM) combines plastic injection molding and powdered metallurgy, offering greater design flexibility for shaping metals like stainless steel, titanium, and copper. The process begins with creating a feedstock of fine metal powders mixed with thermoplastic and wax binders, which is then injected into a mold to form a "green" part. After debinding to remove the binders, the part undergoes sintering at high temperatures to achieve its final strength and geometry, resulting in highly precise, complex components with reduced production costs.