Why Choose

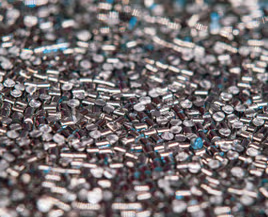

Low Alloy Steel?Metal injection moulding benefits from the exceptional mechanical and physical properties of low alloy steels.Consider low alloy steel when your metal parts call for:

- High hardness

- High strength and structural integrity

- High toughness

- High density

- Machinability

- Adequate corrosion resistance

- Ability to be welded

PERFORMANCE METALS

Alloy Properties and Applications

4602

4602

This cost-effective, heat-treatable grade offers a balanced combination of strength, toughness, and machinability, and it hardens effectively with traditional quench and temper treatments or in a case-hardened condition.

8620

8620

This is a versatile, heat-treatable grade renowned for its exceptional strength, toughness, and wear resistance. It can be effectively used in either the quenched/tempered condition or case-hardened by carburising.

FN0205

FN0205

A medium-carbon, iron-copper-nickel steel with good mechanical properties.

4140 Q&T High Hardness

4140 Q&T High Hardness

A low alloy steel with chromium, molybdenum, and manganese that offers high strength, toughness, and wear resistance when quenched and tempered, and features superior tensile strength, yield strength, and impact resistance compared to wrought 4140.

4140 Q&T Low Hardness

4140 Q&T Low Hardness

A low alloy steel with Chromium, Molybdenum, and Manganese that can be heat-treated to various hardness levels. It offers superior tensile strength, yield strength, and impact resistance compared to wrought 4140.

MIM-4605 (As Sintered)

MIM-4605 (As Sintered)

MIM 4605 offers exceptional strength and good ductility due to its processing and is used across various industries.

MIM-4605 (Quenched & Tempered, High Hardness)

MIM-4605 (Quenched & Tempered, High Hardness)

MIM 4605, a low alloy steel with carbon, nickel, and molybdenum, achieves high hardness and enhanced strength and wear resistance through quench and temper heat treatment.

MIM-4605 (Quenched & Tempered, Low Hardness)

MIM-4605 (Quenched & Tempered, Low Hardness)

MIM 4605, a low alloy steel with carbon, nickel, and molybdenum, achieves low hardness and varying strength and wear resistance through quench and temper heat treatment.

MIM-K3 (Heat Treated)

MIM-K3 (Heat Treated)

MIM-K3, a heat-treated Mo-Fe alloy, offers enhanced fatigue properties while maintaining good strength.

How Our Custom Alloy Choices Drive Innovation

Experience enhanced design freedom and improved quality with our advanced materials.

.png&w=268&q=75)