Uniform Wall Thickness, Coring & Mass Reduction

With MIM, you are not constrained by the design limitations of standard metalworking processes.

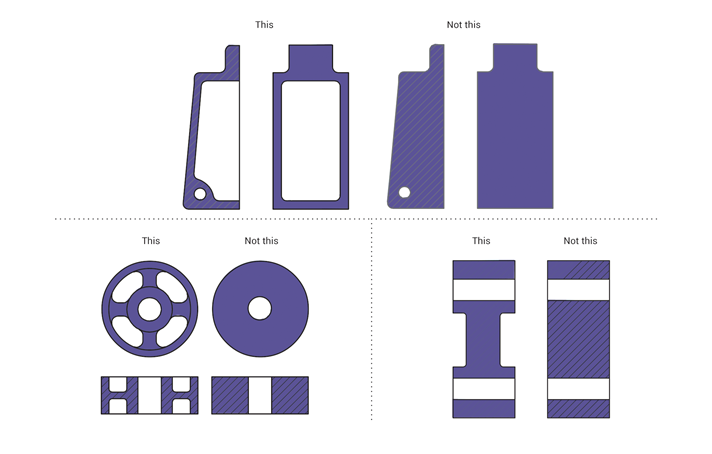

- During the MIM process, our engineers have the freedom to start with a “clean slate” and build up their component geometry by placing material only where it is needed for function and strength

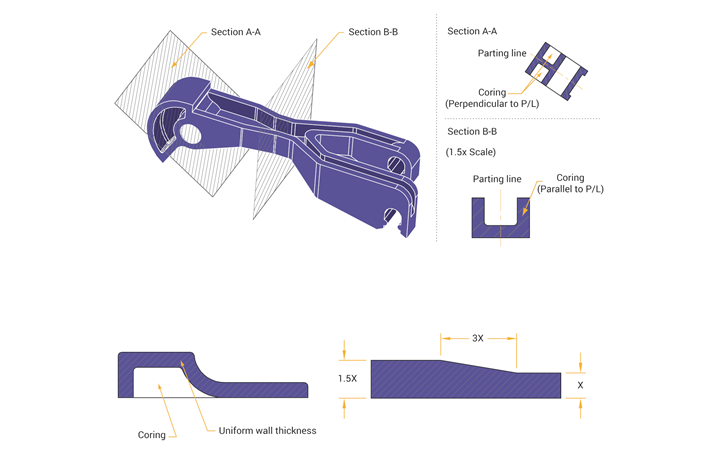

- Coring can help create uniform walls through preferred geometries. There are also instances in the MIM process where unnecessary material is removed or cored out in areas with thick cross-sections. Coring can be done either parallel or perpendicular to the parting line

- Maintaining a uniform wall thickness throughout a component reduces the likelihood of molding process flaws, improving the overall part quality, cosmetics, and generally improving the resulting dimensional tolerances that the MIM process can provide

- Uniform walls are also desired for higher precision, more repeatable dimensional capability, lower processing costs and improved aesthetics