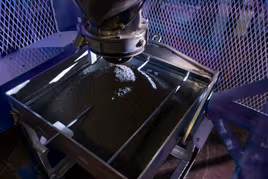

At OptiMIM, a key differentiator is the customizable feedstock, produced in-house. This feedstock is made by combining very fine metal powders with thermoplastic and wax binders in a precise recipe to achieve between 95 and 100% theoretical density and close tolerances over high-production runs.

Making metal injection molding materials to achieve higher strength and density sounds great on paper—but that doesn't even begin to cover all of the problems that can be solved with proprietary feedstock capabilities.

In this webinar, MetalSolutions series veteran John O'Donnell and OptiMIM Engineering and Tooling Manager Steve LeBlanc will cover the many ways MIM materials can solve common manufacturing problems, including:

- Modifying material to suit project requirements

- Creating custom material to suit project requirements

- Achieving higher strength, density, and durability than with powder metallurgy

- Shortening your supply chain

- Greater design freedom, and more!

Please fill out the form to download our free on demand webinar.

.png&w=268&q=75)